08

2025

-

05

The Key Role of WNiFe Tungsten Heavy Alloy Bucking Bars in Aircraft Riveting Processes

The Key Role of WNiFe Tungsten Heavy Alloy Bucking Bars in Aircraft Riveting Processes

In the intricate realm of aircraft manufacturing, precision and reliability are not just desired but absolute necessities. Every component, no matter how seemingly minute, plays a crucial part in ensuring the safety and performance of the final product. Among these components, bucking bars have emerged as indispensable tools, especially in the riveting processes that hold the aircraft structure together. Specifically, WNiFe tungsten heavy alloy bucking bars have taken center stage, revolutionizing the way aircraft riveting is conducted.

Bucking bars are work tools that are positioned behind work surfaces. Their primary function is to act as a backing member during the application of impact fasteners. When riveting, a significant amount of force is exerted on the rivet. The bucking bar, placed on the opposite side of the rivet from the rivet gun, absorbs the shock and provides a stable surface against which the rivet can be deformed to form a bucktail. This process is essential for creating a strong, secure joint that can withstand the extreme conditions an aircraft encounters during flight.

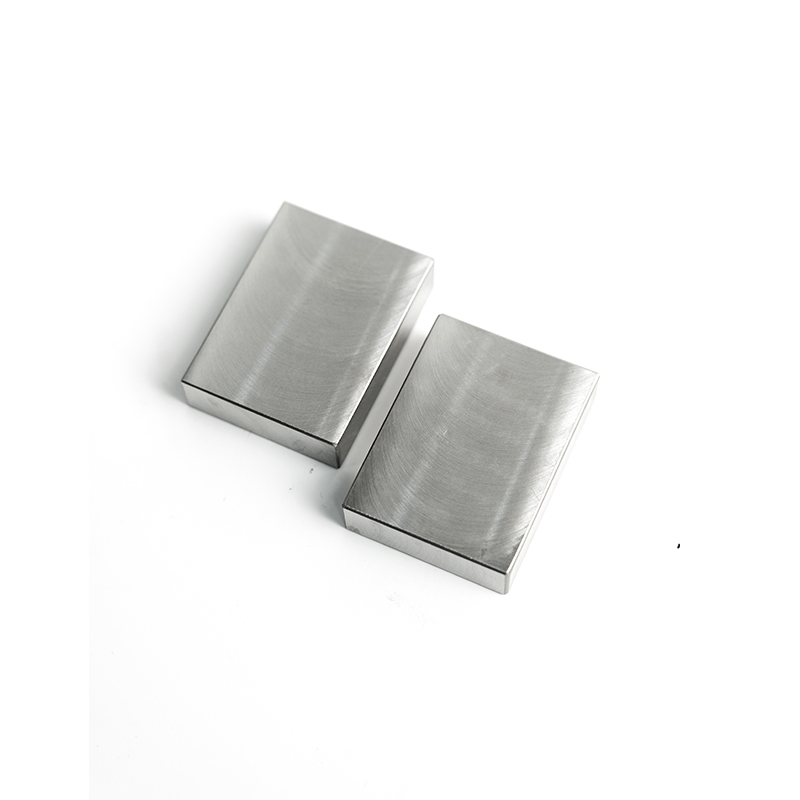

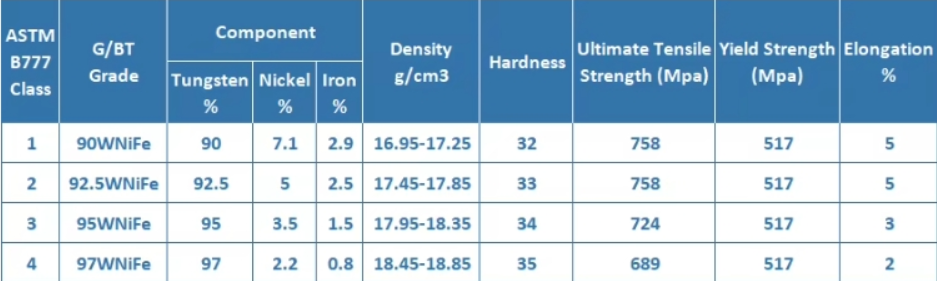

What sets WNiFe tungsten heavy alloy bucking bars apart is their unique composition and properties. Tungsten heavy alloys, primarily composed of tungsten (W), nickel (Ni), and iron (Fe), possess exceptional density, strength, and hardness. These characteristics make them ideal for use as bucking bars in aircraft manufacturing. The high density of the alloy ensures that the bucking bar can effectively absorb the impact energy generated during riveting, reducing the recoil and minimizing the risk of damage to the surrounding structure. This is particularly important in aircraft construction, where the integrity of the material is of utmost importance.

The design of WNiFe tungsten heavy alloy bucking bars further enhances their functionality. They typically consist of an intermittent tool head and handle parts, with a low-recoil impact-absorbing spacer in between. This spacer is a key feature as it takes on the shock loads during the riveting process, protecting the user from excessive vibrations and reducing fatigue. The ergonomic design of the handle ensures a comfortable grip, allowing for precise control during operation.

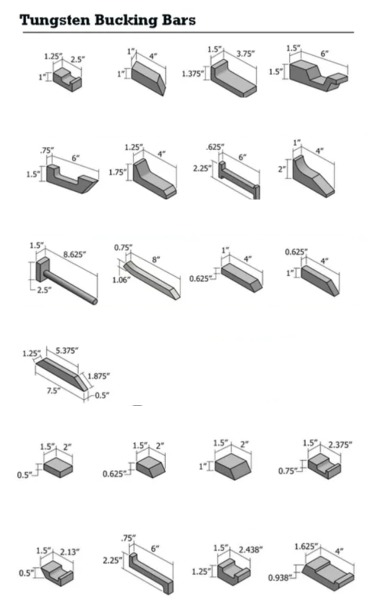

Another significant advantage of WNiFe tungsten heavy alloy bucking bars is their versatility. They come in a wide variety of shapes and sizes, each tailored to specific riveting applications. The choice of shape depends on the location and accessibility of the rivet to be driven. For example, in areas with limited space, a narrow or angled bucking bar may be required to reach the rivet. The ability to customize these bucking bars according to the unique requirements of aircraft manufacturing ensures that every rivet can be installed with the highest level of precision.

In addition to their mechanical properties and design, WNiFe tungsten heavy alloy bucking bars also offer excellent durability. They can withstand repeated use and high-stress conditions without significant wear or deformation. This longevity not only reduces the need for frequent replacements but also contributes to cost savings in the long run. Moreover, their resistance to corrosion ensures that they maintain their performance over time, even in harsh manufacturing environments.

In conclusion, WNiFe tungsten heavy alloy bucking bars play a key role in aircraft riveting processes. Their unique properties, innovative design, versatility, and durability make them essential tools in the aerospace industry. As aircraft manufacturing continues to evolve and demand higher levels of precision and efficiency, these bucking bars will undoubtedly remain at the forefront, ensuring the production of safe, reliable, and high-performance aircraft.

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Přidat215, budova 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

Pošlete nám poštu

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy