Kategorier

Kontakt os

Ultra-Durable Tungsten Carbide Pottery Trimming Tools | Never-Dull Wear-Resistant Carbide Blades for High-Volume Production

E -mail:

E -mail:

Ultra-Durable Tungsten Carbide Pottery Trimming Tools | Never-Dull Wear-Resistant Carbide Blades for High-Volume Production

Professional Tungsten Carbide Pottery Tools - The Ultimate Solution for High-Volume Ceramic Production

I. Product Overview

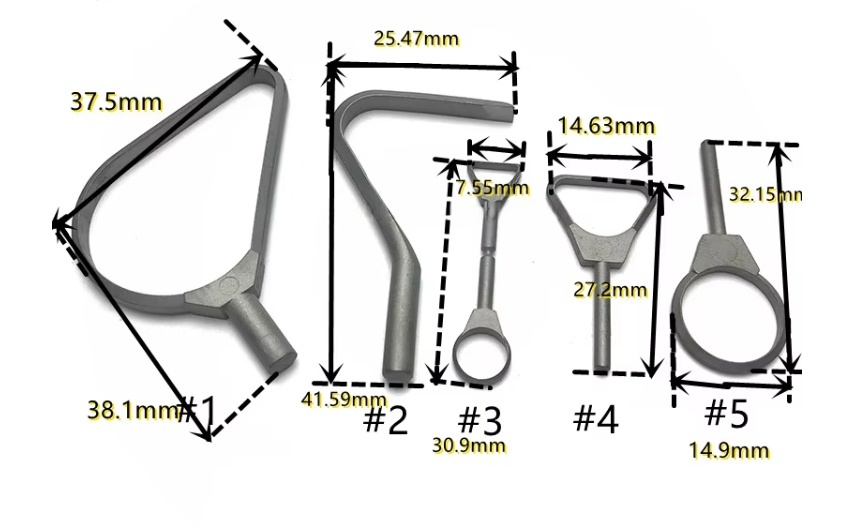

Our Tungsten Carbide Pottery Tools are designed specifically for high-intensity use in professional ceramic studios, art schools, and production potteries. By utilizing industrial-grade tungsten carbide tips, these tools maintain a razor-sharp edge even when working with highly abrasive clay bodies (stoneware, porcelain with grog).

II. Technical Excellence & Specifications

| Feature | Details | Advantage |

| Blade Material | K20/K30 Tungsten Carbide (HRA 90-92) | Extremely wear-resistant; minimal sharpening required. |

| Handle Options | Premium Hardwood / Anodized Aluminum / Stainless Steel | Ergonomic and durable for long-shift usage. |

| Blade Thickness | 1.5mm - 2.5mm (Customizable) | High precision with zero bending under pressure. |

| Connection | Epoxy Bonded + Mechanical Fastening | Guaranteed no-loose-head, even in wet conditions. |

OEM / ODM & Bulk Services

We understand the needs of brand owners and distributors:

Logo Laser Engraving: Custom branding on handles or blades for orders over 100 pcs.

Custom Shapes: We can manufacture specific blade geometries based on your technical drawings or samples.

Packaging Solutions: Bulk packaging for studios or retail-ready blister packs/gift boxes for distributors.

Stable Lead Times: Monthly capacity of 50,000 units ensures your inventory remains consistent.

Why Source Our Carbide Tools?

Cost Efficiency (High ROI): While the initial cost is higher than steel, the lifespan is 50-100 times longer, significantly lowering the "cost-per-use" for your clients or studio.

Superior Performance: High hardness means cleaner cuts, less drag on the wheel, and no "shattering" on leather-hard clay, resulting in a higher quality finished product.

Market Competitiveness: Offer your retail customers or students a premium "Pro-Grade" tool that stands out from generic hobbyist sets.

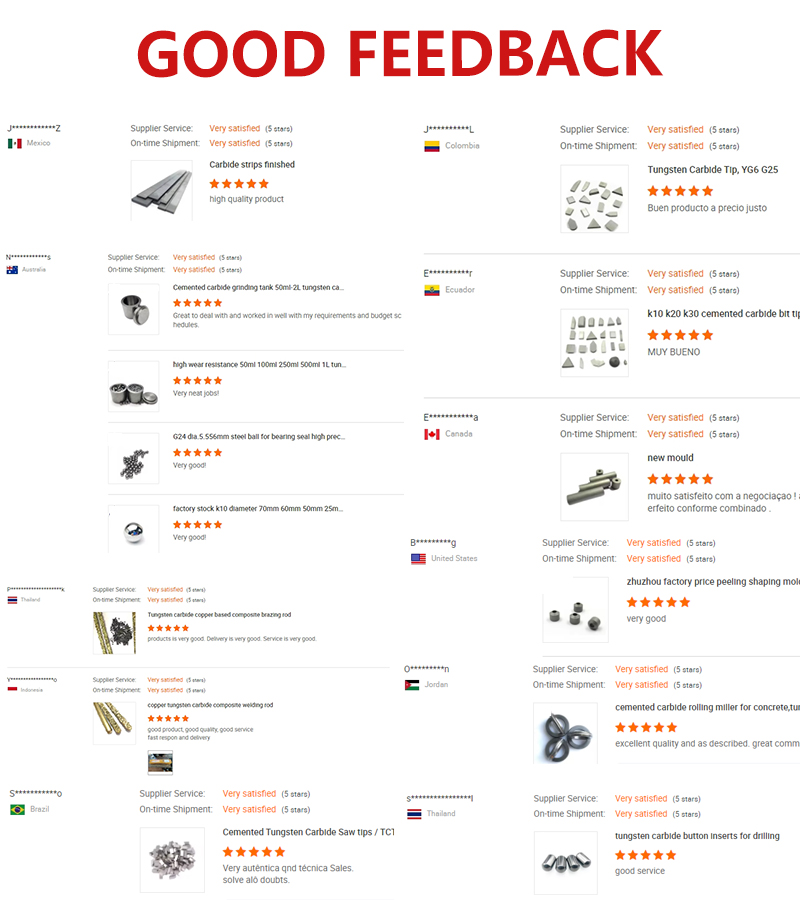

Quality Control (QC)

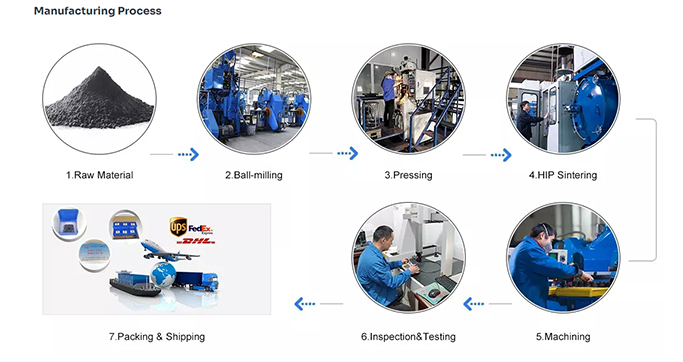

Every tool undergoes a rigorous inspection process:

Material Hardness Testing to ensure carbide grade.

Blade Sharpness Check for consistent cutting performance.

Stress Testing on the handle-to-blade joint.

Shipping & Logistics

MOQ: Flexible starting from 50 pieces (sample orders supported).

Shipping: Experience with DDP/DAP terms via Sea, Air, or Express (DHL/FedEx/UPS).

Compliance: All materials are rust-resistant and designed for long-term storage in varied climates.

Ofte stillede spørgsmål:

Q1: Er du fabrik eller handelsvirksomhed?

Vi er fabrik med 12 års produktionserfaring.

Q2: Hvor er din fabrik placeret?

Vi er beliggende i Zhuzhou by, Hunan-provinsen, hvor er basen af wolframcarbid.

Q3: Er prisen konkurrencedygtig?

Vi har vores egen fabrik. Takket være et stærkt produktions- og distributionssystem lover vi at tilbyde vores kunder den mest konkurrencedygtige pris.

Q4: Er produkterne af høj kvalitet?

Ja. Alle produkter vil blive testet før bulkproduktion, og vi vil kontrollere de fysiske egenskaber, form og tolerance for at sikre kvalificerede produkter inden forsendelse.

Du er velkommen til at kontakte mig:

Aimee

Salgschef

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

E-mail:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688

Relaterede produkter

Send os mail

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Tilføje215, bygning 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

Send os mail

Ophavsret :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy