Kategorije

Kontaktirajte nas

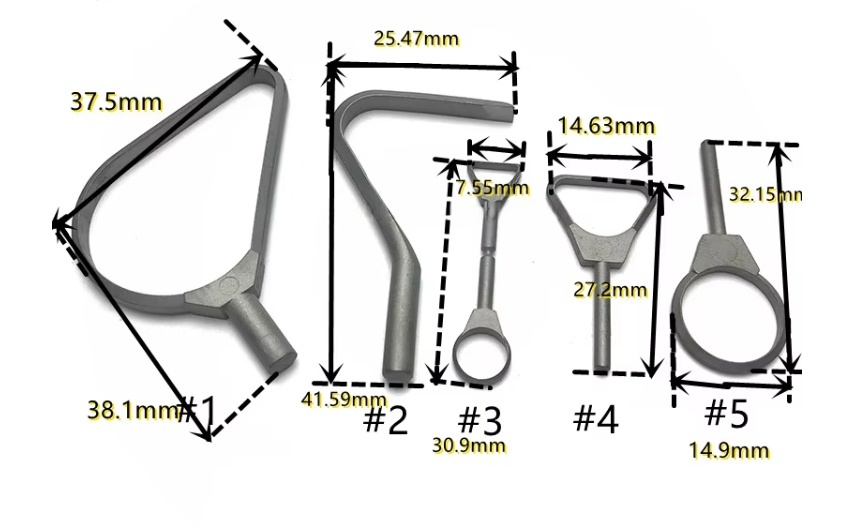

Versatile Tungsten Carbide Pottery Tools with Multiple Blade Shapes | Professional Grade Clay Sculpting & Trimming Set

E -pošta:

E -pošta:

Versatile Tungsten Carbide Pottery Tools with Multiple Blade Shapes | Professional Grade Clay Sculpting & Trimming Set

Professional Tungsten Carbide Pottery Tools - The Ultimate Solution for High-Volume Ceramic Production

I. Product Overview

Our Tungsten Carbide Pottery Tools are designed specifically for high-intensity use in professional ceramic studios, art schools, and production potteries. By utilizing industrial-grade tungsten carbide tips, these tools maintain a razor-sharp edge even when working with highly abrasive clay bodies (stoneware, porcelain with grog).

II. Technical Excellence & Specifications

| Feature | Details | Advantage |

| Blade Material | K20/K30 Tungsten Carbide (HRA 90-92) | Extremely wear-resistant; minimal sharpening required. |

| Handle Options | Premium Hardwood / Anodized Aluminum / Stainless Steel | Ergonomic and durable for long-shift usage. |

| Blade Thickness | 1.5mm - 2.5mm (Customizable) | High precision with zero bending under pressure. |

| Connection | Epoxy Bonded + Mechanical Fastening | Guaranteed no-loose-head, even in wet conditions. |

OEM / ODM & Bulk Services

We understand the needs of brand owners and distributors:

Logo Laser Engraving: Custom branding on handles or blades for orders over 100 pcs.

Custom Shapes: We can manufacture specific blade geometries based on your technical drawings or samples.

Packaging Solutions: Bulk packaging for studios or retail-ready blister packs/gift boxes for distributors.

Stable Lead Times: Monthly capacity of 50,000 units ensures your inventory remains consistent.

Why Source Our Carbide Tools?

Cost Efficiency (High ROI): While the initial cost is higher than steel, the lifespan is 50-100 times longer, significantly lowering the "cost-per-use" for your clients or studio.

Superior Performance: High hardness means cleaner cuts, less drag on the wheel, and no "shattering" on leather-hard clay, resulting in a higher quality finished product.

Market Competitiveness: Offer your retail customers or students a premium "Pro-Grade" tool that stands out from generic hobbyist sets.

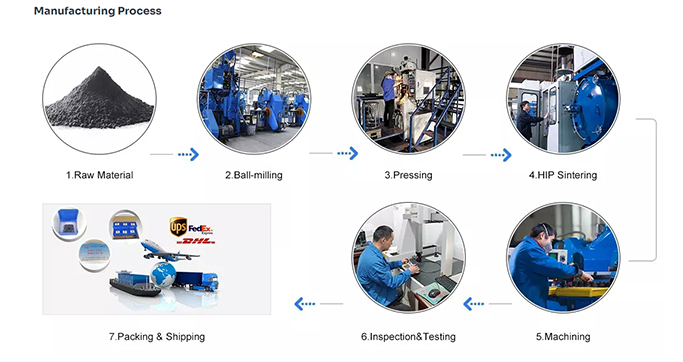

Quality Control (QC)

Every tool undergoes a rigorous inspection process:

Material Hardness Testing to ensure carbide grade.

Blade Sharpness Check for consistent cutting performance.

Stress Testing on the handle-to-blade joint.

Shipping & Logistics

MOQ: Flexible starting from 50 pieces (sample orders supported).

Shipping: Experience with DDP/DAP terms via Sea, Air, or Express (DHL/FedEx/UPS).

Compliance: All materials are rust-resistant and designed for long-term storage in varied climates.

FAQ:

P1: Jeste li tvornica ili trgovačko poduzeće?

Mi smo tvornica s 12 godina iskustva u proizvodnji.

P2: Gdje se nalazi vaša tvornica?

Nalazimo se u gradu Zhuzhou, provinciji Hunan gdje je baza volfram karbida.

P3: Je li cijena konkurentna?

Imamo vlastitu tvornicu. Zahvaljujući snažnom proizvodnom i distribucijskom sustavu, obećavamo našim kupcima ponuditi najkonkurentniju cijenu.

P4: Jesu li proizvodi visoke kvalitete?

Da. Svi će proizvodi biti testirani prije masovne proizvodnje, a mi ćemo provjeriti fizička svojstva, oblik i toleranciju kako bismo osigurali kvalificirane proizvode prije otpreme.

Slobodno me kontaktirajte:

Aimee

Voditelj prodaje

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Okrug Tianyuan, Grad Zhuzhou.

Email:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

Povezani proizvodi

Pošaljite nam poštu

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Dodati215, zgrada 1, Pioneer Park međunarodnih studenata, Taishan Road, Tianyuan District, Zhuzhou City

Pošaljite nam poštu

Autorska prava :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy