Kategorijos

Susisiekite su mumis

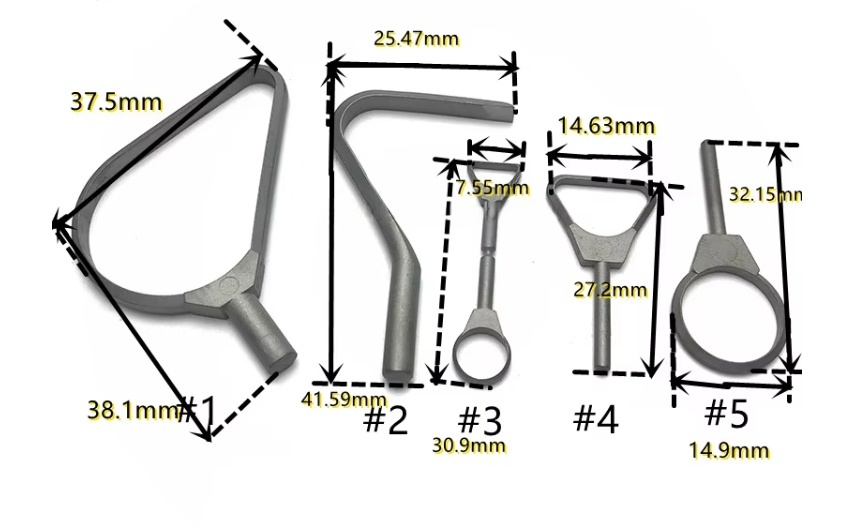

Ultra-Durable Tungsten Carbide Pottery Trimming Tools | Never-Dull Wear-Resistant Carbide Blades for High-Volume Production

El. Paštas:

El. Paštas:

Ultra-Durable Tungsten Carbide Pottery Trimming Tools | Never-Dull Wear-Resistant Carbide Blades for High-Volume Production

Professional Tungsten Carbide Pottery Tools - The Ultimate Solution for High-Volume Ceramic Production

I. Product Overview

Our Tungsten Carbide Pottery Tools are designed specifically for high-intensity use in professional ceramic studios, art schools, and production potteries. By utilizing industrial-grade tungsten carbide tips, these tools maintain a razor-sharp edge even when working with highly abrasive clay bodies (stoneware, porcelain with grog).

II. Technical Excellence & Specifications

| Feature | Details | Advantage |

| Blade Material | K20/K30 Tungsten Carbide (HRA 90-92) | Extremely wear-resistant; minimal sharpening required. |

| Handle Options | Premium Hardwood / Anodized Aluminum / Stainless Steel | Ergonomic and durable for long-shift usage. |

| Blade Thickness | 1.5mm - 2.5mm (Customizable) | High precision with zero bending under pressure. |

| Connection | Epoxy Bonded + Mechanical Fastening | Guaranteed no-loose-head, even in wet conditions. |

OEM / ODM & Bulk Services

We understand the needs of brand owners and distributors:

Logo Laser Engraving: Custom branding on handles or blades for orders over 100 pcs.

Custom Shapes: We can manufacture specific blade geometries based on your technical drawings or samples.

Packaging Solutions: Bulk packaging for studios or retail-ready blister packs/gift boxes for distributors.

Stable Lead Times: Monthly capacity of 50,000 units ensures your inventory remains consistent.

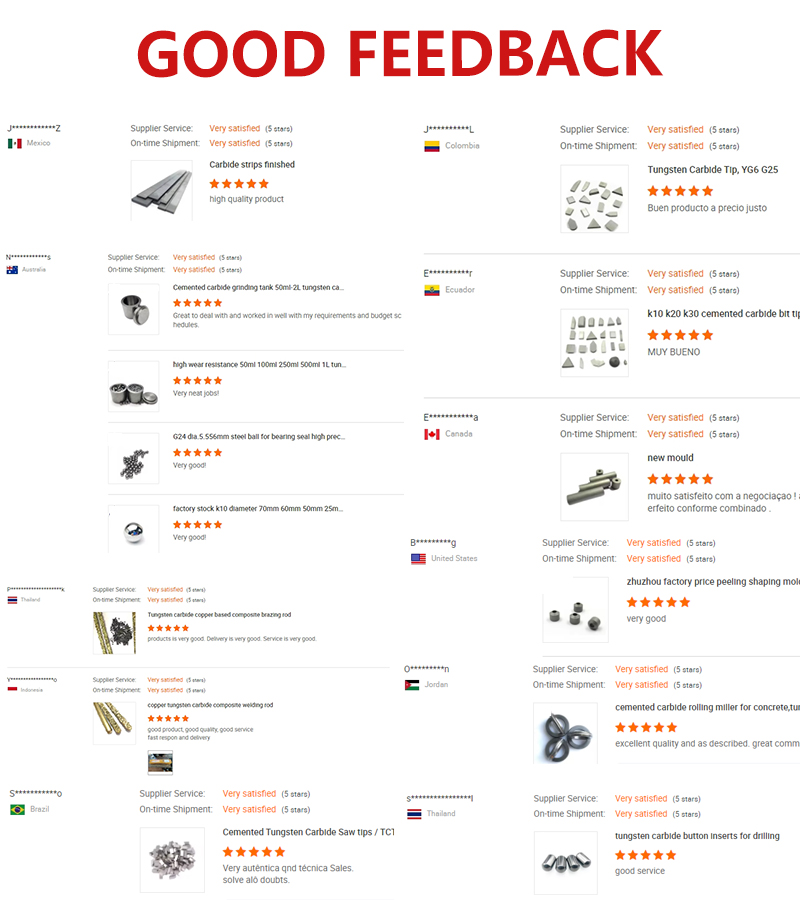

Why Source Our Carbide Tools?

Cost Efficiency (High ROI): While the initial cost is higher than steel, the lifespan is 50-100 times longer, significantly lowering the "cost-per-use" for your clients or studio.

Superior Performance: High hardness means cleaner cuts, less drag on the wheel, and no "shattering" on leather-hard clay, resulting in a higher quality finished product.

Market Competitiveness: Offer your retail customers or students a premium "Pro-Grade" tool that stands out from generic hobbyist sets.

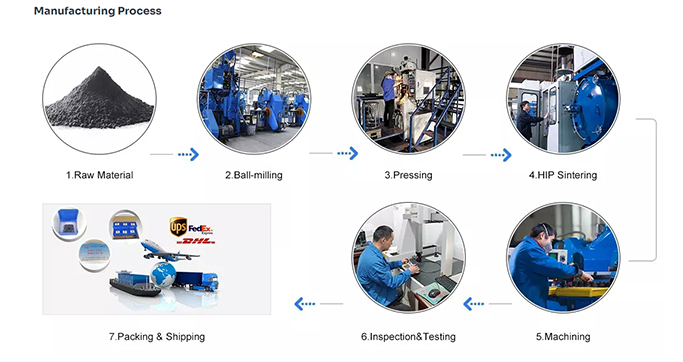

Quality Control (QC)

Every tool undergoes a rigorous inspection process:

Material Hardness Testing to ensure carbide grade.

Blade Sharpness Check for consistent cutting performance.

Stress Testing on the handle-to-blade joint.

Shipping & Logistics

MOQ: Flexible starting from 50 pieces (sample orders supported).

Shipping: Experience with DDP/DAP terms via Sea, Air, or Express (DHL/FedEx/UPS).

Compliance: All materials are rust-resistant and designed for long-term storage in varied climates.

DUK:

Q1: Ar esate gamykla ar prekybos įmonė?

Esame gamykla, turinti 12 metų gamybos patirtį.

2 klausimas: kur yra jūsų gamykla?

Esame įsikūrę Zhuzhou mieste, Hunano provincijoje, kur yra volframo karbido bazė.

3 klausimas: ar kaina yra konkurencinga?

Mes turime savo gamyklą. Stiprios gamybos ir platinimo sistemos dėka savo klientams žadame pasiūlyti konkurencingiausią kainą.

4 klausimas: ar produktai yra aukštos kokybės?

Taip. Visi gaminiai bus išbandyti prieš masinę gamybą, o prieš išsiunčiant patikrinsime fizines savybes, formą ir toleranciją, kad užtikrintume kvalifikuotus gaminius.

Nedvejodami susisiekite su manimi:

Aimee

Pardavimų vadybininkas

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianjuano rajonas, Džudžou miestas.

El. paštas:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688

Susiję produktai

Atsiųskite mums paštą

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Pridėti215, 1 pastatas, Tarptautinis studentų pionierių parkas, Taishan Road, Tianyuan rajonas, Zhuzhou miestas

Atsiųskite mums paštą

Autorių teisės :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy