21

2025

-

11

Carbide Jaw Inserts: Models, Applications & Selection Guide

Carbide Jaw Inserts: Models, Applications & Selection Guide

Carbide jaw inserts are essential wear-resistant components used in clamping, gripping, and positioning systems. Thanks to their outstanding hardness, durability, and resistance to deformation, they ensure stable clamping performance and improve machining accuracy across various industries.

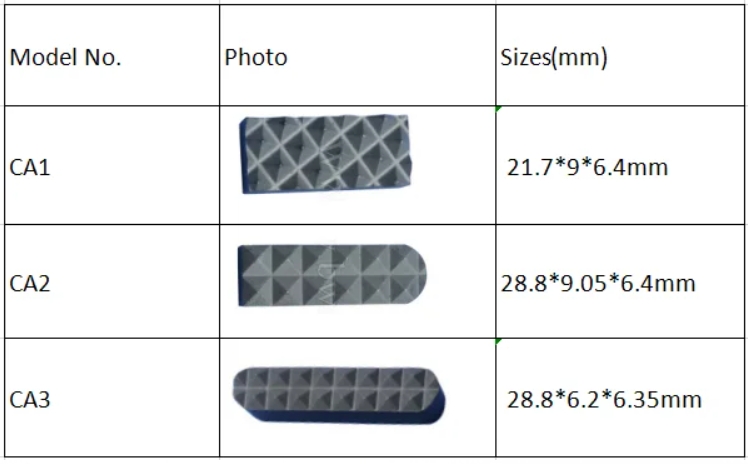

1. Common Models

Although the design varies among manufacturers, most carbide jaw inserts fall into several widely used categories:

• Serrated Jaw Inserts

These inserts have coarse or fine teeth on the surface to increase friction and gripping force.

Typical use: metal processing, oil & gas tools, pipe handling equipment, and heavy-duty gripping systems.

• Smooth Jaw Inserts

Flat, toothless surfaces designed to protect the workpiece from scratches or deformation.

Typical use: automotive and aerospace parts, precision machining, and surface-sensitive components.

• V-Shaped Jaw Inserts

Specially designed for clamping round bars, rods, pipes, and tubular components.

Typical use: machining fixtures, repair tools, drilling support systems.

• Customized Inserts

Produced based on specific drawings or equipment requirements, such as wide-tooth inserts, high-impact inserts, or heat-resistant designs.

Typical use: special clamping tools, drilling jaws, robotic grippers, high-load equipment.

2. Applications

Carbide jaw inserts are widely used in industries that require strong, stable, and repetitive clamping:

• Machining & Tooling

Lathe chucks, milling fixtures, grinding clamps—ensuring reliable positioning and minimizing slippage.

• Oil & Gas Industry

Used for gripping drill pipes, tubing, and downhole tools, where high torque and vibration resistance are essential.

• Automotive & Aerospace

Precision component clamping where surface protection and high stability are equally important.

• Robotics & Automation

Applied in robot end-effectors and automated workstations requiring long service life and high repeatability.

• Maintenance & Heavy-Duty Tools

Pipe wrenches, gripping pliers, and industrial repair tools to increase grip strength and durability.

3. Selection Guide

To choose the right carbide jaw insert, consider the working environment, the required gripping force, and the type of workpiece.

① Material Grade

Common carbide grades include YG6, YG8, YG10, and YG15.

YG6: higher hardness, excellent wear resistance; ideal for low-impact conditions.

YG8 / YG10: balanced hardness and toughness.

YG15: superior impact resistance; suitable for high vibration or heavy-load applications.

② Shape & Surface Structure

Serrated for maximum friction and grip

Smooth for protecting delicate surfaces

V-type for securing round workpieces

Wide-tooth or fine-tooth depending on required grip strength and application stability

③ Working Conditions

Key considerations include:

Is there high impact or vibration?

Does the application involve high temperature?

Is lubrication present (oil, coolant)?

Does the workpiece tend to slip?

These factors determine both the material grade and the ideal structural design.

4. Conclusion

Carbide jaw inserts may be small components, but they play a crucial role in overall equipment performance. Choosing the right model and grade ensures stable clamping, reduces downtime, and significantly improves working efficiency and tool life.

Talafeagai Tala

Zhuzhou Chuangde Sima Carbide Co., Ltd

Faaopoopo215, fale 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

Lafo mai ia matou meli

Pule Tau Fatuga :Zhuzhou Chuangde Sima Carbide Co., Ltd

Sitemap

XML

Privacy policy