30

2025

-

10

Tungsten Carbide Rolls: Manufacturing Process, Properties, and Industrial Applications

Tungsten Carbide Rolls: Manufacturing Process, Characteristics, and Application

Tungsten carbide rolls, also known as cemented carbide rolls, are essential components used in rolling mills for forming and shaping metal materials. They are made from a composite material consisting of tungsten carbide (WC) as the hard phase and cobalt (Co) or nickel (Ni) as the binder phase.

Due to their exceptional hardness, wear resistance, and strength at high temperatures, tungsten carbide rolls have gradually replaced traditional steel rolls in many high-precision and high-load rolling applications.

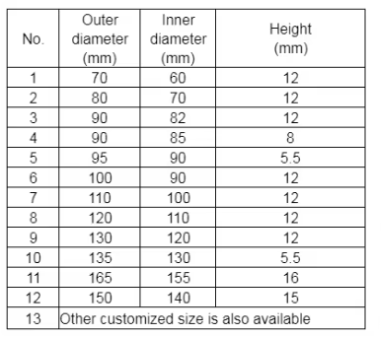

Carbide rolls are one of the materials most needed by steel mills. They are mainly divided into four categories: high-speed wire rod rolls, new generation high-speed hot wire rod rolls, new generation high-speed wire rod rolls, and cold-rolled 3D coils.

1. Manufacturing Process

The production of tungsten carbide rolls involves precise powder metallurgy techniques and multiple processing stages:

Powder Preparation

Ball Milling and Mixing

Pressing (Compaction)

Sintering

Machining and Finishing

Assembly (for Composite Rolls)

2. Characteristics of Tungsten Carbide Rolls

High Hardness and Wear Resistance

The hardness of tungsten carbide (typically above 85 HRA) ensures excellent resistance to wear and deformation during rolling.

Excellent Strength and Thermal Stability

Maintains mechanical properties even under high temperature and high pressure conditions.

Superior Surface Quality and Dimensional Accuracy

Ensures smooth rolling surfaces and consistent product dimensions.

Corrosion and Oxidation Resistance

Performs well even in harsh or humid working environments.

Long Service Life and Reduced Maintenance

3. Applications

Tungsten carbide rolls are widely used in the steel and non-ferrous metal industries, especially in high-speed and precision rolling lines, such as:

Wire Rod and Bar Mills – Finishing and intermediate stands for producing wire rods, bars, and rebars.

Tube and Pipe Mills – Sizing and reducing rolls for seamless and welded tubes.

Strip Mills – Precision rolling of narrow strips and special sections.

Non-Ferrous Rolling – Copper, aluminum, and alloy rolling operations.

Specialty Applications – Used in flattening, straightening, and forming processes requiring high wear resistance.

Conclusion

Tungsten carbide rolls represent the perfect balance between hardness, toughness, and durability, making them an indispensable tool in modern rolling mill technology.

With advancements in powder metallurgy and precision machining, these rolls continue to deliver higher productivity, improved product quality, and lower operational costs, supporting the ongoing evolution of the global metallurgical industry.

Wararka La Xiriira

Hal qayb oo ka mid ah Zhuzhou Chuangde Cemented Carbide Co., Ltd

Xisaab isku darid215, dhismaha 1, Ardayda Caalamiga ah ee Pioneer Park, Taishan Road, Degmada Tianyuan, Magaalada Zhuzhou

U soo dir boostada

Xuquuqda daabacaadda :Hal qayb oo ka mid ah Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy