20

2024

-

06

Melemo ea carbiside e noella ka holim'a tšepe ke efe?

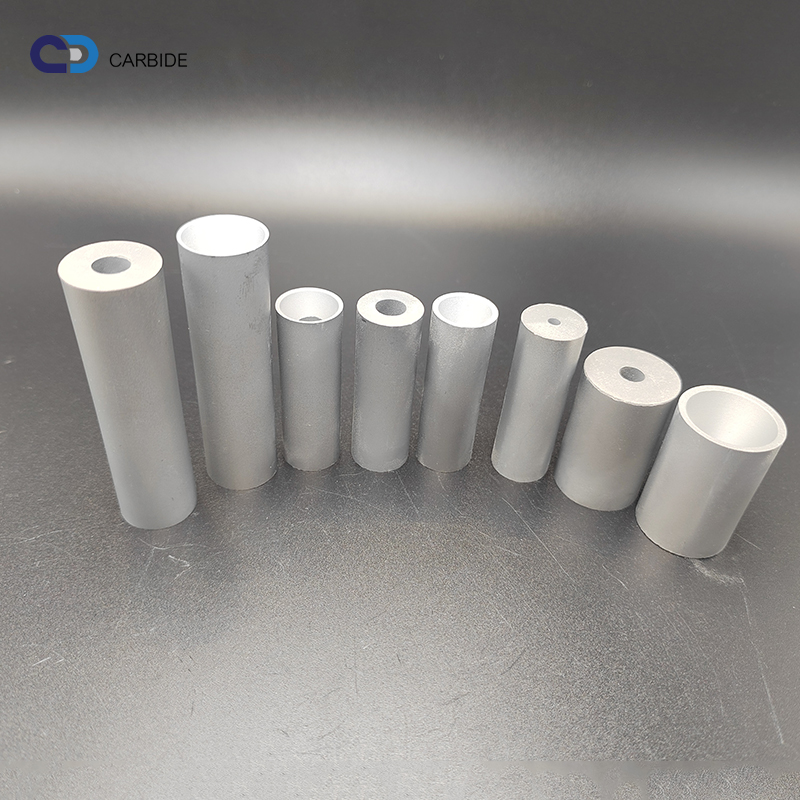

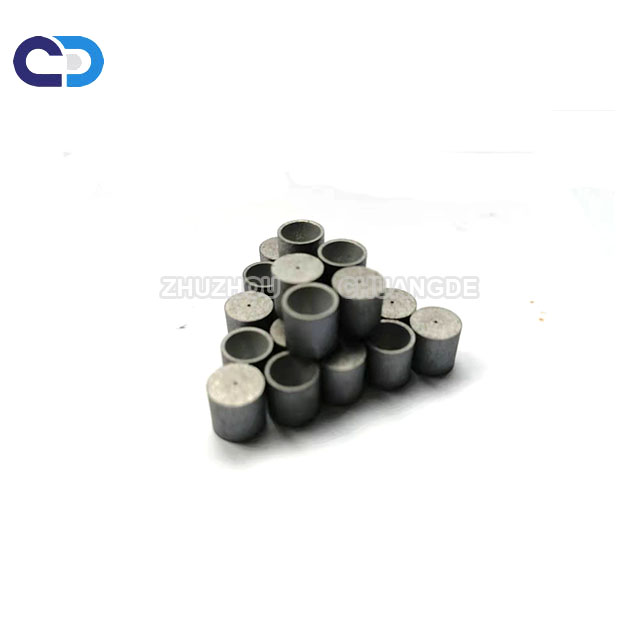

Likarolo tsa mantlha tsacebide e halikiloeng ea carmentide ke carbide carbide (wc) le cobalt (co). Har'a bona, kokelo ea makoloi ke karolo e thata ea nang le thata e thata 'me u rorisise; Cobalt ke karolo ea ho ba bonolo e ka ntlafatsang matla le ho theola matla a hae.

Ntle le WC le CO, e kanna ea boela e na le lintho tse ling tse kang Tatium (Tima), chrodium (v), jj.

Molemo:

Tsela e le hantle

2. Resifar

3.SLLARER ea mocheso o phahameng oa mocheso o phahameng

4.Pood e bolokiloeng

Ka mohlala, ka mocheso o phahameng ka matla, melemo ea li-notble tsa indasteri, ho ka ba le maemo a tloaelehileng a ho sebetsa kapele; Tikoloho e nang le lik'hemik'hale tse matla, ho hanyetsa ha ho hanela ho beoa ha mabota a kopaneng ho ka tiisa ts'ebetso ea eona e tšepahalang, empa tšepe e ka tsamaisoa habonolo.

Ts'ebetsong ea satane, ke mekhoa efe e ka sebelisoang ho ntlafatsa ho hanyetsa ho hanyetsa ha ho hanyetsa lemene se kopantsoeng se halikiloeng?

1.optimize lillo

2.use e tsoetseng pele lits'ebetso tsa boitokisetso ba litokisetso

3.Soufface kalafo

Moralo oa "Rable "e nang le sebopeho sa nozzle

5.Contel sandblateraterate ea litšoantšo

Tlhokomelo ea kamehla le ho fumana sebaka: Lekola ho roala chefo, 'me u nke sebaka sa ho roala ka thata ka nako ea ho qoba ho ama katleho le boleng.

Kopo:

1. Ho hloekisa

2.Sandblasting

3.Seba e futhumatsang

4.Siction ea 4. furu

Ts'ebetso e 5.Coating

6.Pomide e fafatsa

Ka bokhutšoanyane, carbide nozzles e bapala karolo ea bohlokoa masimong a mangata a indasteri le tebeletso ka lebaka la ho hanyetsa ha a hanyetsa, ho hanyetsa ha mocheso o phahameng le ho fafatsa haholo.

Sehlahisoa sa rona se bonts'a:

Litaba tse Amanang

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Eketsa215, mohaho oa 1, Phaka ea Bopula-maliboho ba Liithuti tsa Machaba, Tsela ea Taishan, Setereke sa Tianyuan, Motse oa Zhuzhou

Re romelle mangolo

Copyright :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy