28

2025

-

04

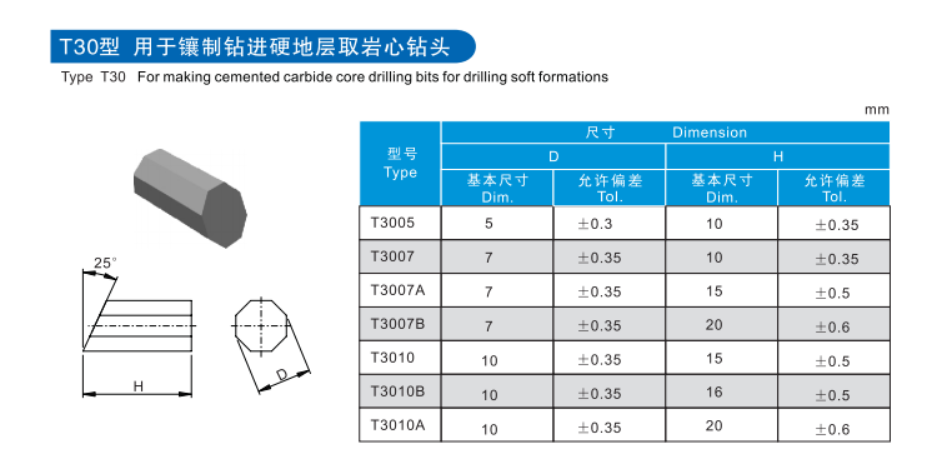

Ts'ebetso ea Octagonal le ts'ebeliso

Tšimong ea ts'ebetso ea sejoale-joale ea liindasteri, likeletso tsa actaGonal li lula li le boemong ba bohlokoa ka ts'ebetso ea bona e ntle. Ka moralo oa 'ona o ikhethang oa occranal o bile o fetohile sesebelisoa se "bohale" sa ho sebetsana le lisebelisoa tse fapaneng.

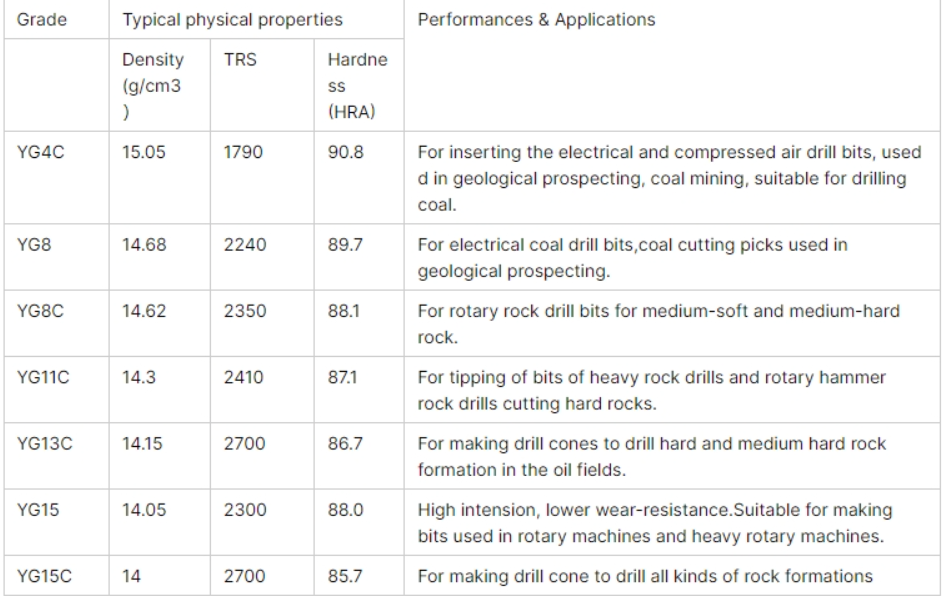

Ha lebitso le bontša, ntlheng ea octagonal e ka sehloohong ke octagonal ka sebopeho. Moralo ona o ikhethang o etsa hore o be o hatisitsoe haholo nakong ea seharuri, e fokotsa ho roala lisebelisoa le ho ntlafatsa botsitso ba ho sebetsa. Lintho tsa eona li entsoe haholo ka li-carbides tsa tšepe tsa meriti (joalo ka li-tungsten carbide wc) le ho tlama litloaelo (joalo ka cobalt C). Ka phofo ea metallirgy, lisebelisoa tsena li etsoa likeletso ka thata le ho roala khanyetso e phahameng. Ka mocheso oa kamore, ho thata ha Carbide le ka fihla 86-93RA, e lekanang le 69-81HRC. Le mocheso o phahameng oa 900-1000 ℃, e ntse e ka ba le mathata a maholo. Ntho ena e thata ho e fihlela bakeng sa malebela a mang a tloaelehileng.

Malebela a tšepe a lebelo le phahameng, malebela a octaGonal a na le mathata a holimo mme a le matla ho hanyetsa. Ho thata ha li-blade tsa lebelo le phahameng haholo hangata ho 62-67RC. Ha tekanyo e thata ka lebelo le phahameng, tekanyo ea moaparo e potlakile haholo ho feta ea li-brades tsa carbide. Le ha ho thata ho ba le mabele a feberu ea waceici ho ka fihlela batho ba fetang 90h, ba thatafala ebile ba tloaetse ho chechisa. Ha u ntse u bolela thata ka thata, 'mala oa octaganal o na le ho ba thata' me o ka khona ho mamella tlhokahalo e itseng.

Carbide Octagonal e sebelisoa haholo. Ka indasteri ea tšepe le boitlamo ba koloi, e sebelisoa ho hlophisa likarolo tsa senotlolo joalo ka li-cylinders tsa enjene le boleng ba likarolo tsa bokaholimo; Tšimong ea Aerospace, e ka fokotsa lisebelisoa tse thata tse kang Titanuys le liphihlelo tse thehiloeng ho Titanuld Ka indasteri ea lihlahisoa tsa elektroniki, likarolo tsa ts'ebetso ea ho lokisa le ho se hoho ho botoro li se ke tsa aroloa ho eona. E ka fihlela ts'ebetso ea bohlokoa haholo 'me e kopane le litekanyetso tse thata tsa ho nepahala ha boleng bo nepahetseng le boleng ba lihlahisoa tsa lihlahisoa tsa elektroniki. Indastering ea Ts'ebetso ea Lehong, ebang ea sema le ho ithipa ts'ebetso ea thepa ea ka tlung, ho sebetsa ha parchina ho ka phethela mosebetsi o itseng. Indastering ea ho lokisa majoe, e boetse e bapala karolo ea bohlokoa ea ho rema, ho sesa, ho betla kabo, granite, lejoe le betliking.

Ho na le lintlha tse ngata tseo u lokelang ho nahana ka tsona ha u khetha hlooho e loketseng oa cuteganol Cutter. Ea pele ke mofuta oa thepa ea ho sebetsa. Haeba u ntse u sebetsa thepa ka thata e phahameng, u lokela ho khetha hlooho ea seha ka thata ka sekhahla se phahameng le ho roala seriti se betere; Ha u sebetsana le thepa ea "brittle thepa ea brittle, o lokela ho ela hloko ho thatafalloa ha hlooho e sehiloeng ho thibela ho chechisa. Ea bobeli ke ntho ea ho nepahala ha ts'ebetso ea ts'ebetso. Bakeng sa ts'ebetso ea ho lokisa haholo, ho nepahala ha moeli le botsitso ba hlooho ea sehiloeng ke ea bohlokoa. Ntle le moo, ho seha likarolo tse kang ho senyeha le sekhahla sa ho fepa le hona ho boetse ho kenyelletsa khetho ea hlooho ea se se nang hlooho. Mekhoa e fapaneng ea ts'ebetso e hloka lihlooho tsa cuteter ka liparanta tse tsamaeang.

Ho na le mehato e mengata ea ho ba hlokolosi ha u sebelisa Carbisisi ea Cutter ea Chogonal. Taolo e hlokang thuso ea ho seha paramente ke senotlolo. Lebelo la ho kuta le sekhahla se sehiloeng le sekhahla sa ho fepa ho tla eketsa ho roala hloohong ea metsi le ho baka tšenyo ea hlooho ea sehiloeng. Ka hona, hoa hlokahala ho khetha liparathara tse nepahetseng ho latela lisebelisoa tsa ho sebetsa le tšebetso ea hlooho ea seha. Ho boetse hoa hlokahala hore u hlahlobe seaparo sa hlooho ea sehiloeng. Ha hlooho ea Cuter e apere ka tekanyo e itseng, e tla ama ho nepahala ha ts'ebetso le boleng ba ts'ebetso. Ka nako ena, e lokela ho nkeloa sebaka ka nako. Ka nako e ts'oanang, etsa mosebetsi o motle oa ho hloekisa le ho boloka sesebelisoa sa ho qoba likhohlano tsa se se nang kutu. Kamora ho sebetsa, hloekisa li-chip tsa ho kuta ka nako ea ho thibela maseru le ho holisa lijalo tsa tšebeletso.

Carbide Octagonal Headter Lithapo tsa lihlooho tsa li-indastering ea ho kena indastering e mengata le moralo oa tsona o ikhethang le ts'ebetso e ntle. Ho utloisisa litšobotsi tsa eona le ho sebelisa lintlha tsa bohlokoa tsa ho khetha le ho sebelisa lintlha le ho li bapalla ho molemo le boleng ba mosebetsi.

Litaba tse Amanang

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Eketsa215, mohaho oa 1, Phaka ea Bopula-maliboho ba Liithuti tsa Machaba, Tsela ea Taishan, Setereke sa Tianyuan, Motse oa Zhuzhou

Re romelle mangolo

Copyright :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy