28

2025

-

04

Ukusebenza kweengcebiso ze-Ocimagonial kunye nesicelo

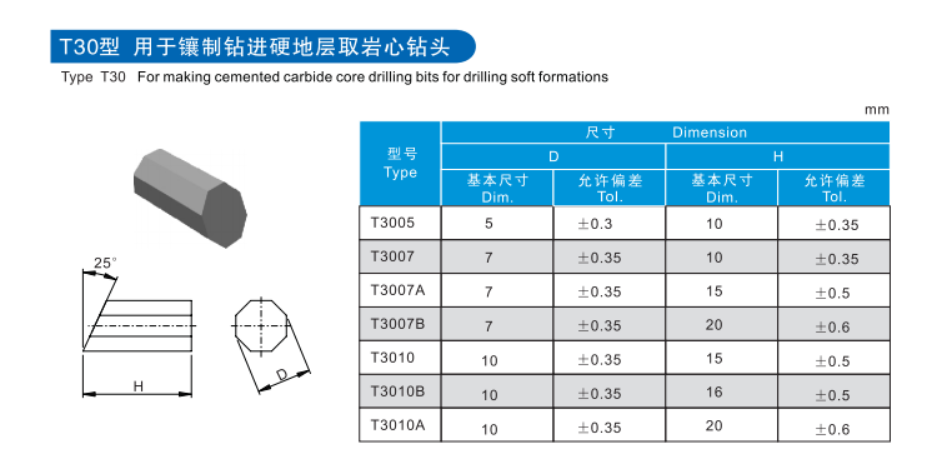

Kwintsimi yenkqubo yokulungisa imizi-mveliso, i-carbide ye-ocagonal isebenzisa indawo ebalulekileyo ngokusebenza kwabo ngokugqibeleleyo. Ngoyilo lwayo le-OCtagonal eyahlukileyo kunye nempahla ye-carbide, iye yaba "sisixhobo esibukhali" sokwenza izixhobo ezahlukeneyo.

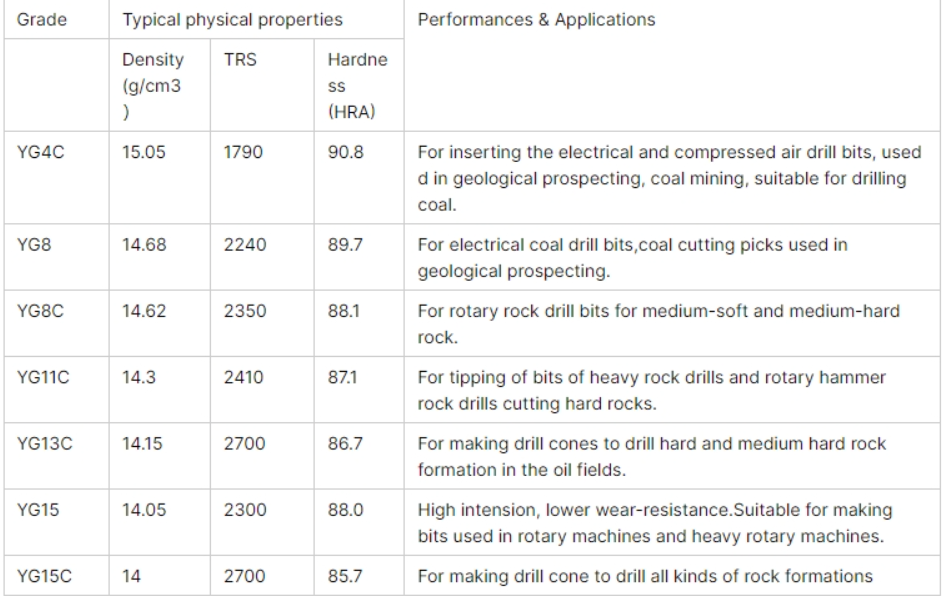

Njengoko igama libonisa, inkcitho ye-carbide ocagonal i-ocagonal kwimo. Olu luyilo olukhethekileyo lwemibumo lwenza ukuba kube lula ukugxininiswa kakhulu ngexesha lokusika, kunciphisa ukusetyenziswa kwesixhobo kunye nokuphucula ukuzinza. Izinto zayo zenziwe ikakhulu yi-carbric yentsimbi ye-carby (ezinje nge-tungsten ye-tungsten wc) kunye ne-bounds yentsimbi (efana neCobalt Co). Ngomgubo we-powder, ezi zinto zenziwa zicebiso malunga nobunzima obuphakathi kunye nokunganyangeki okuphezulu. Kubushushu begumbi, ubunzima be-carbide bunokufikelela kwi-86-93hra, elingana ne-69-813HRC. Kwanakwiqondo lobushushu eliphezulu lama-900-1000 ℃, lisenokugcina ubunzima obukhulu. Eli nqaku linzima ukufezekisa ezinye iingcebiso zezixhobo eziqhelekileyo.

Xa kuthelekiswa neengcebiso zensimbi yensimbi ephezulu, iingcebiso ze-carbide ze-carbide zineengxaki eziphezulu kunye nokunganyangeki. Ubunzima beentsimbi zensimbi ephezulu yensimbi yi-62-67hrc. Xa usike okanye ukuqhubekisa izixhobo ezinzima ngesantya esiphezulu, ireyithi yexabiso ingxamise ngokukhawuleza kunezo zeBlads ze-carbide. Nangona ubunzima be-ceramic blades bunokufikelela ngaphezulu kwe-90hra, banamahlwempu kwaye banomdla wokuphosa. Ngelixa kuqinisekisa ubunzima obuphakamileyo, ii-carbide zeotagonal blades zinobunzima obuhle kwaye zinokumelana nemithwalo ethile yefuthe.

I-carbide ocagonal blades isetyenziswa ngokubanzi. Kwimveliso yokuqhutywa kwentsimbi kunye nemveliso yemoto, isetyenziselwa ukuqhubela phambili iinxalenye eziphambili ezinjengezilinda zenjini kunye ne-crankshafts ukuqinisekisa ukuba inqanaba eliphezulu kunye nendawo ephezulu yenxalenye; Kwintsimi ye-aerospace, inokusika izinto ezinzima-nkqubo ezinjenge-Altinays Alloys kunye ne-Alfleys-esekwe kwi-NECKEL-esekwe kwiimfuno ezinqabileyo zeenqwelo moya. Kumzi-mveliso wokwenza izinto ze-elektroniki, ukulungisa izinto ngokuchanekileyo kunye nokusika ibhodi yesekethe kungathengi kuyo. Inokufezekisa ukuqhubela phambili okuphezulu kwaye ihambelane nemigangatho engqongqo yolungelelwano kunye nomgangatho womhlaba weemveliso ze-elektroniki. Kumzi mveliso wokulungisa iinkuni, nokuba incipha kwaye iphosakele ekwenzisweni kwefanitshala okanye ukuqhubela kwenkuni kumhlobiso wezixhobo, ii-carbide zearheckonial zinokugqibezela umsebenzi. Kwishishini lokuqhubela kwelitye, ikwadlala indima ebalulekileyo ekunciphiseni, ukugaya iMarble, Granite, kunye nelitye.

Zininzi izinto ekufuneka ziqwalaselwe xa ukhetha intloko yesikizi efanelekileyo. Owokuqala luhlobo lwezinto ezisebenzayo. Ukuba uqhuba umbandela onobunzima obuphezulu, kuya kufuneka ukhethe intloko yokusika ngobunzima obuphezulu kunye nokunxiba ngcono ukunyangwa; Xa kuqhutywa izinto zeBrittle, kufuneka unikele ingqalelo kubunzima bentloko yesikithi yokuthintela ukuchithwa. Okwesibini yimfuno yokuchaneka kwemfuneko. Ukulungiswa okucocekileyo okuphezulu, ukuchaneka komda kunye nokuzinza kwentloko yesikitshi kubalulekile. Ukongeza, ukusika iiparameter njengesantya sokusika kunye nexabiso londla kuya kuchaphazela ukukhetha kwentloko yesikithi. Iinkqubo ezahlukeneyo zokulungisa zifuna iintloko zesikizi ngeeparamitha ezihambelanayo.

Zininzi iindlela zokuthintela xa kusetyenziswa iintloko ze-carbide chebide. Ulawulo olufanelekileyo lweeparameter ezisikiweyo sisitshixo. Isantya esigqithisileyo kunye nexabiso londla liya kwandisa ukunxiba kwentloko yesikizi kwaye nokubangela ukonakala kwintloko yesikithi. Ke ngoko, kuyimfuneko ukukhetha iparameters efanelekileyo ngokwezinto zokusebenza kunye nokusebenza kwentloko yesikithi. Kuyimfuneko ukuphinda ujonge ukusetyenziswa kwentloko yesikithi. Xa intloko yokusika inxibe ukuya kuthi ga kwinqanaba elithile, iya kuchaphazela ukuchaneka kokulungiswa kunye nomgangatho womhlaba. Ngeli xesha, kufuneka itshintshwe ngexesha. Kwangelo xesha, yenza umsebenzi omuhle wokucoca nokulondolozwa kwesixhobo ukuphepha ukonakaliswa kwentloko yesikithi. Emva kokuqhubekeka, ukucoca iitshiphu kunye nokuhlawula intsalela kwintloko yesikithi ngexesha ukunqanda ukuqhuma kunye nokulungela, ukuze kwandise ubomi benkonzo yentloko.

Iintloko zokusika ii-carbide ze-carbide ze-ocagonali zidlala indima engenakufikelelwa kumashishini amaninzi ngeyilo labo eyodwa kunye nokusebenza ngokugqibeleleyo. Ukuqonda iimpawu zayo kunye nokusebenzisa amanqaku aphambili okhetho kunye nokusetyenziswa kuya kunceda ukudlala ngcono izibonelelo zayo kwaye kuphuculwe ukusebenza kunye nomgangatho.

Iindaba ezinxulumene noko

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Yongeza215, isakhiwo 1, Abafundi beZizwe ngezizwe Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

Thumela i-imeyile

Ilungelo lokushicilela :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy