28

2025

-

04

Amathiphu we-Octagonal ukusebenza kanye nesicelo

Emkhakheni wezezimboni zezimboni zanamuhla, amathiphu we-carbide octagonal ahlala esikhundleni esibalulekile ngokusebenza kwawo okuhle. Ngokwakheka kwayo okuhlukile kwe-octagonal ne-octagonal ne-carbide, sekuphenduke "ithuluzi elibukhali" lokucubungula izinto ezahlukahlukene.

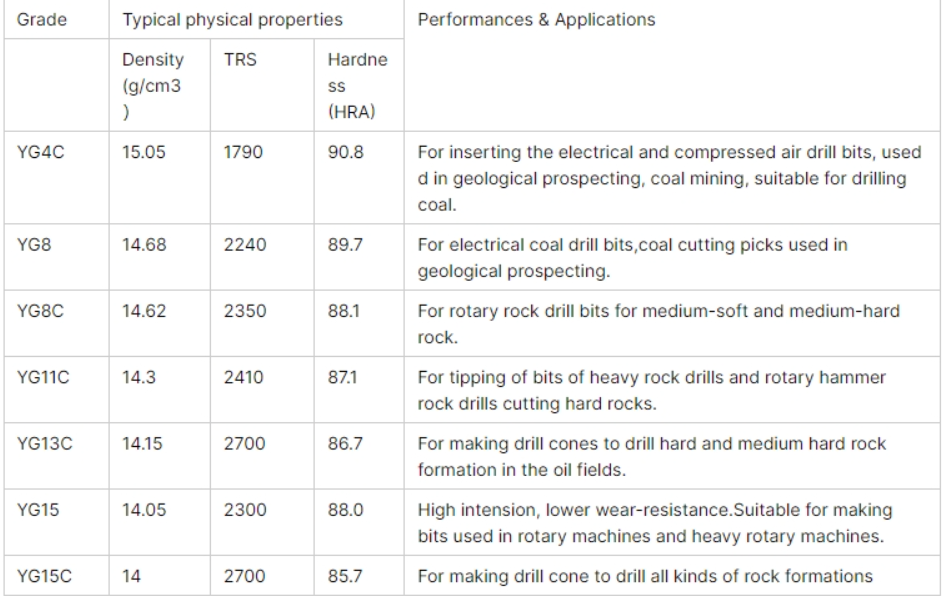

Njengoba igama libonisa, ithiphu ye-octagonal ye-carbide yi-octagonal ngesimo. Lo mklamo okhethekile wesimo wenza ukuthi icindezelwe ngokulinganayo ngesikhathi senqubo yokusika, inciphisa ithuluzi lokugqoka futhi lithuthukise ukucubungula ukuqina. Izinto zayo ikakhulukazi zakhiwa nge-carbides yensimbi eyi-refractory (efana neTungsten Carbide WC) kanye nezinsimbi ezibophayo (njenge-cobalt co). Ngokusebenzisa i-powder metluggy, lezi zinto zokwenziwa zenziwa ngezeluleko ngobulukhuni obuphezulu nokumelana nokugqoka okuphezulu. Ekushiseni kwekamelo, ubulukhuni be-carbide bungafinyelela ku-86-93hhra, okulingana no-69-81hrc. Ngisho nasemazingeni okushisa aphezulu angu-900-1000 ℃, kusengagcina ubulukhuni obuphezulu. Lesi sici kunzima ukufeza amanye amathiphu ajwayelekile ezintweni ezibonakalayo.

Uma kuqhathaniswa namathiphu wensimbi anesivinini esikhulu, amathiphu we-carbide octagonal anobulukhuni obuphakeme kanye nokuvimbela okunamandla okuqinile. Ubulukhuni bama-blades ensimbi anesivinini esikhulu ngokuvamile 62-67HRC. Lapho usika noma ucubungula izinto ezinzima ngesivinini esikhulu, izinga lokugqoka lishesha kakhulu kunalelo le-carbide blades. Yize ubulukhuni bama-ceramic blade bungafinyelela ngaphezu kwe-90hra, banobunzima obubi futhi bathambekele ekuphumeni. Ngenkathi iqinisekisa ubulukhuni obuphezulu, ama-carbide octagonal blades anobunzima obuhle futhi akwazi ukumelana nemithwalo ethile yethonya.

Ama-Carbide Octagonal blades asetshenziswa kabanzi. Embonini yensimbi yokucubungula kanye nokukhiqiza izimoto, kusetshenziselwa ukucubungula izingxenye ezibalulekile ezifana nama-cylinders enjini kanye nama-crankshaft ukuqinisekisa ukunemba okuphezulu kanye nekhwalithi ephezulu yezingxenye; Ensimini ye-aerospace, ingasika izinto ezinzima ukucubungula njenge-titanium alloys kanye nama-alloys asuselwa ku-nickel ukuze ahlangabezane nezidingo eziqinile zezingxenye zezindiza. Embonini yezokwakha elekthronikhi, ukucutshungulwa kwezingxenye ngokunemba nokusika kwe-Circuity ahlukanisiwe kuyo. Kungakuthola ukucubungula okunembayo futhi kuhlangane namazinga aqinile wokunemba okubucayi kanye nekhwalithi ephezulu yemikhiqizo ye-elekthronikhi. Embonini yokucubungula izinkuni, noma ngabe ukusika nokuqopha ekukhiqizweni kwefenisha noma izinkuni ukucubungula umhlobiso wezakhiwo, ama-carbide octagonal blades angawuqedela kahle umsebenzi. Embonini yezamatshe, futhi kudlala indima ebalulekile ekusikeni, ukugaya imabula, i-granite kanye nokubaza ngamatshe.

Kunezici eziningi okufanele zicatshangelwe lapho ukhetha i-Carbide Carbide Cartagonal cuter cutter cutter cuter. Owokuqala uwuhlobo lwezinto ezisebenzayo. Uma ucubungula impahla enobulukhuni obuphakeme, kufanele ukhethe inhloko eyi-cuter ngobulukhuni obuphakeme kanye nokuvikeleka okungcono; Lapho ucubungula izinto zokwakha ama-brittle, kufanele unake ubunzima bekhanda le-cutter ukuvikela ukukhishwa. Okwesibili yisidingo sokunemba sokunemba. Ngokucutshungulwa okunembayo, ukunemba okunqenqemeni nokuqina kwekhanda le-cutter kubalulekile. Ngaphezu kwalokho, ukusika amapharamitha anjengesivinini sokusika kanye nesilinganiso sokuphakelwa kuzothinta nokukhethwa kwekhanda le-cutter. Izinqubo ezahlukahlukene zokucubungula zidinga amakhanda ama-cutter anamapharamitha ahambisanayo.

Kunezinyathelo eziningi zokuphepha lapho usebenzisa amakhanda we-carbide octagonal cutter cutter cutter. Ukulawulwa okunengqondo kwamapharamitha wokusika kuyisihluthulelo. Isivinini esikhulu sokusika kanye nesilinganiso sokuphakelwayo sizokwandisa ukugqokwa kwekhanda le-cutter futhi kubangele ukulimala kwekhanda le-cutter. Ngakho-ke, kuyadingeka ukuthi ukhethe amapharamitha wokusika afanele ngokuya ngezinto ezisebenzayo kanye nokusebenza kwekhanda le-cutter. Kuyadingeka futhi ukubheka njalo ukugqokwa kwekhanda le-cutter. Lapho ikhanda le-cutter ligqokwa ngezinga elithile, lizothinta ukunemba okusebenzayo kanye nekhwalithi ephezulu. Ngalesi sikhathi, kufanele ithathelwe indawo ngesikhathi. Ngasikhathi sinye, yenza umsebenzi omuhle wokuhlanza nokugcina ithuluzi lokugwema ukugcwala kwekhanda le-cuter. Ngemuva kokucutshungulwa, hlanza ama-chip kanye nokusika okusalayo koketshezi ekhanda le-cutter ngesikhathi ukuvimbela ukugqwala nokugqwala, ukuze kunwetshwe impilo yenkonzo yekhanda le-cutter.

Izinduna ze-Carbide Octagonal Cutter zidlala indima engenakuphikwa ezimbonini eziningi ngomklamo wazo oyingqayizivele kanye nokusebenza okuhle kakhulu. Ukuqonda izici zalo kanye nokukwazi kahle amaphuzu asemqoka wokukhethwa nokusetshenziswa kuzosiza ekudlaleni kangcono izinzuzo zako futhi kuthuthukise ukusebenza kahle nekhwalithi.

Izindaba Ezihlobene

Inkampani Zhuzhou Chuangde Cemented Carbide Co., Ltd

Enezelela215, isakhiwo 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

Sithumele imeyili yase-US

Ilungelo lobunikazi :Inkampani Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy