CATEGORIES

CONTACT US

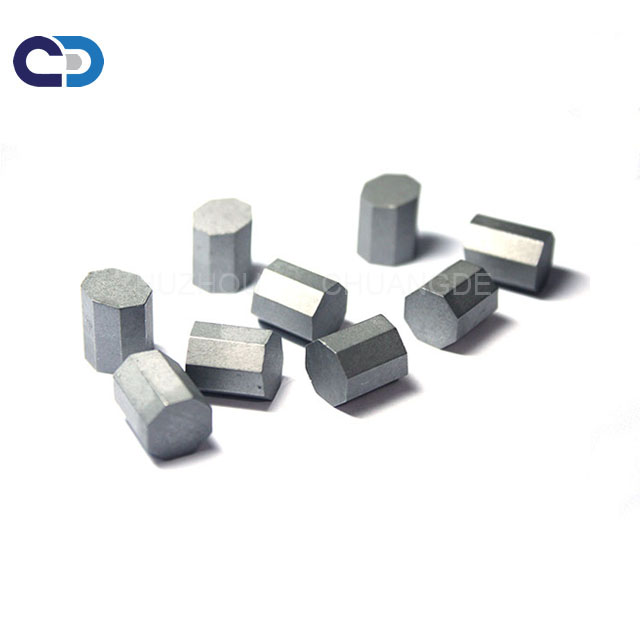

Tungsten Carbide Octagonal Button Inserts for Core Drill Bits for Mineral Mining OEM

Email:

Email:

Tungsten Carbide Octagonal Button Inserts for Core Drill Bits for Mineral Mining OEM

Description of tungsten carbide octagons buttons inserts tips

Description of tungsten carbide octagons buttons inserts tips

| Product Name | Tungsten Carbide Octagonal Inserts for Core Drill Bits for Mineral Exploration |

| Material | 100% Tungsten carbide |

| Color | Gray |

| Brand | CD Carbide |

| Grade | YG8/YG8C/YG11C |

| Application | Mining drill bits |

| Shape | Octagonal |

| Usage | Coal mining |

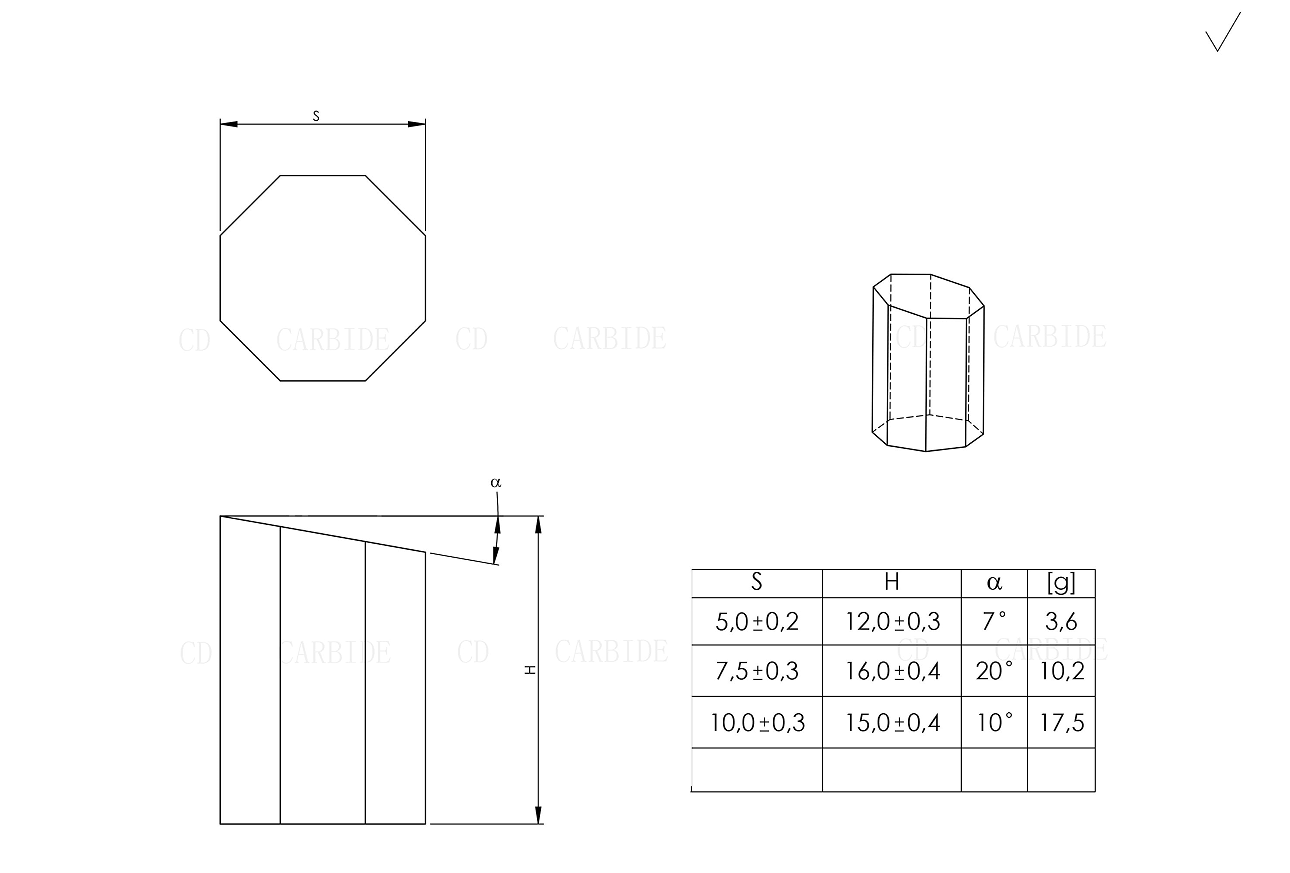

| Size | φ7*10 mm,φ7*15 mm,φ7.5*16,φ5*12 mm , etc. |

CD CDirect Sell Tungsten Carbide Octagonal Tips Button for Mining Rock Drilling

General information for tungsten carbide teeth in octagonal shape:

Fixed on the drill bit by brazing, suitable for soft, medidum hard and hard rock formations drilling.

Two impotant things for brazing:

*Clean surface: Not only means keep the surface cleance, but also need to check the carburization/decarburization carefully.

*Size control: Good size control is also important, size need to be even from the top to the bottom of the tips (within +/- 0.1mm).

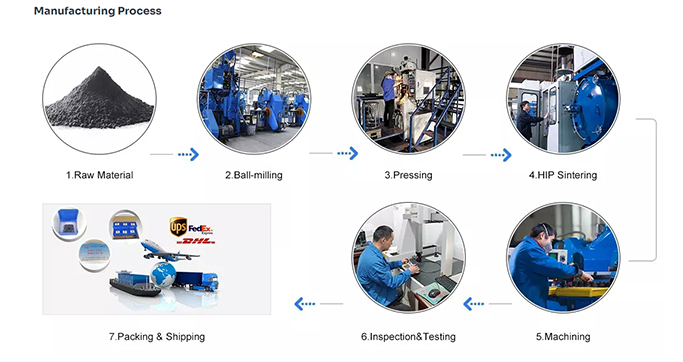

Our tips was done by HIP sintering, it provide extra 30% on bending strength compare to normal quality, which means our tips will be strong enough when meet heavy impact. Also, it will have longer tool life (better wear resistance) for you to use our tips.

*Sinter-HIP is a method of thermal consolidation for cemented carbide wherein the simultaneous application of heat and pressure fully consolidates the carbide during the sintering process.

It is very important to select the right grade to match the using purpose, need to find the perfect balance between hardness and bending strength, so we have to consider the physical properties of the processing object, also the working condition for tools, like running speed, impact.

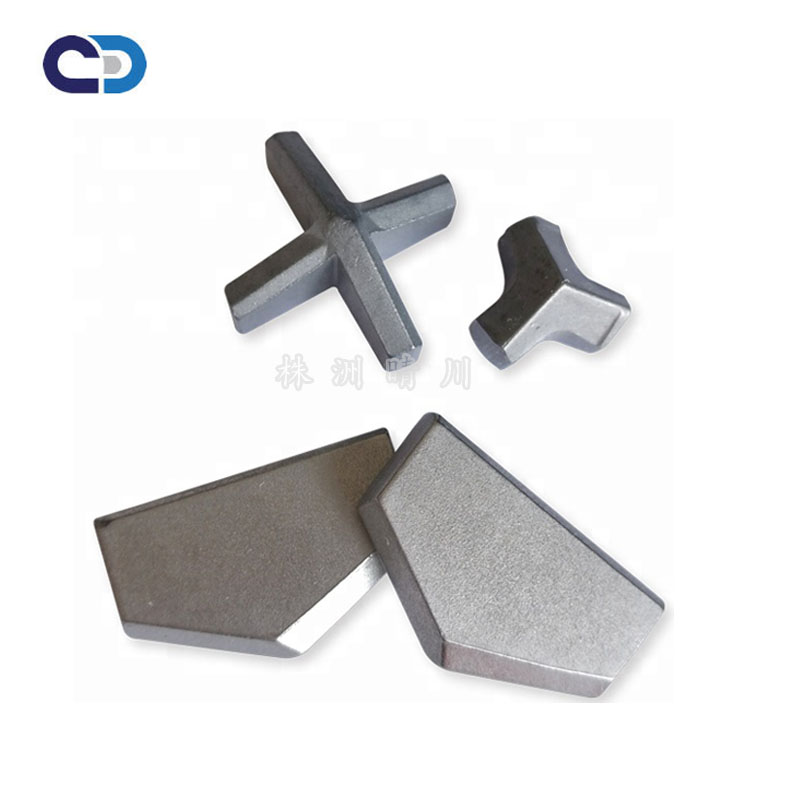

Tungsten carbide button are used in manufacturing drilling and mining equipments(mainly for dth Drill bits & Top-Hammer Drill Bits) which are used in drilling,mining, quarrying , water well drilling and other applications.

we procure carbide buttons from well-known suppliers who have state of the art infrsastructure and highly qualified engineers .our carbide buttons are made in technologically advanced machines which are designed to give products a total reliability,durability and complete customer satifcation.our supplier has own tungsten carbide mines so all the carbide buttons are made of 100% pure and geniuine tungsten powder.

Grade of cemented carbide octagons buttons inserts tips

| Grade | Density | T.R.S | Hardness | Performance & application recommended | Approx Grades in China |

| g/cm3 | MPα | HRA | |||

| CD6 | 14.9 | 2100 | 90 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, usd in geological prospecting, coal mining and oil well boring. | YG6 |

| CD6.1 | 14.7 | 2400 | 89.5 | For coring crowns, electric coal drill bits, coal cutting picks, cone drill bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. | YG8 |

| CD15 | 14 | 2500 | 87.5 | Good strength and less wear resistance, for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. | YG15 |

| CD10 | 14.7 | 2450 | 88.5 | Mostly used as the buttons of small and mediumsized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. | YG8C |

| CD151 | 14.7 | 2450 | 87.8 | Suitable to strips, conical buttons for rotary,percussion-resistant, geological prospecting,buttons, cut soft and medium hard formations. | YK15/YG9C |

| CD20 | 14.4 | 2550 | 87 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. | YK20/YG10C |

| CD25 | 14.5 | 2600 | 87.5 | Primarily for the buttons and inserts of rotary percussion bits to cut medium hard and very hard formations. | YK25 |

| CD30 | 14.4 | 2600 | 87 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. | YG11C |

| CD40 | 14.2 | 2650 | 86.5 | Predominatly for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and vey hard formations. | YK40/YG13C |

| CD50 | 14 | 2700 | 86.5 | For oil cone drill bits, for medium soft and medium -hard rocks. | YG15C |

Other grades may be offered by customers' requirements.

DIMENSION (MM)

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy