28

2025

-

04

Octagonal Tips performance and application

In the field of modern industrial processing, carbide octagonal tips occupy an important position with their excellent performance. With its unique octagonal tip design and carbide material, it has become a "sharp tool" for processing various materials.

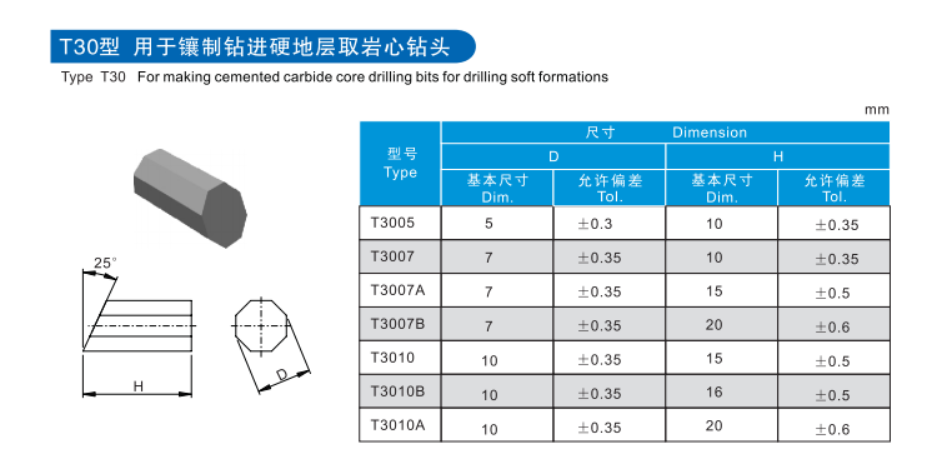

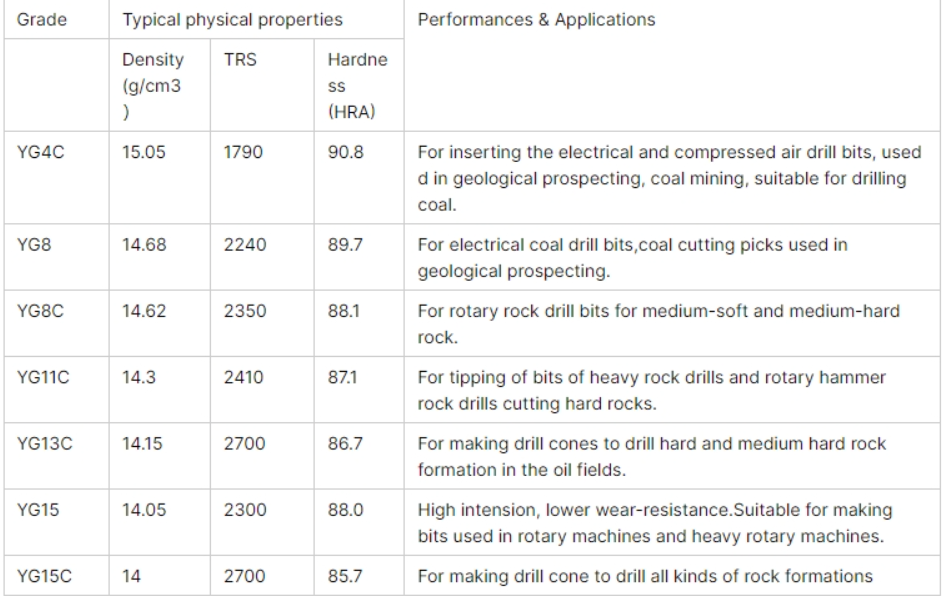

As the name suggests, the carbide octagonal tip is octagonal in shape. This special shape design makes it more evenly stressed during the cutting process, reduces tool wear and improves processing stability. Its material is mainly composed of refractory metal carbides (such as tungsten carbide WC) and bonding metals (such as cobalt Co). Through powder metallurgy, these materials are made into tips with high hardness and high wear resistance. At room temperature, the hardness of carbide can reach 86-93HRA, equivalent to 69-81HRC. Even at high temperatures of 900-1000℃, it can still maintain a high hardness. This feature is difficult to achieve for other ordinary material tips.

Compared with high-speed steel tips, carbide octagonal tips have higher hardness and stronger wear resistance. The hardness of high-speed steel blades is generally 62-67HRC. When cutting or processing hard materials at high speed, the wear rate is significantly faster than that of carbide blades. Although the hardness of ceramic blades can reach more than 90HRA, they have poor toughness and are prone to chipping. While ensuring high hardness, carbide octagonal blades have relatively good toughness and can withstand certain impact loads.

Carbide octagonal blades are widely used. In the metal processing industry and automobile manufacturing, it is used to process key parts such as engine cylinders and crankshafts to ensure high precision and surface quality of parts; in the aerospace field, it can cut difficult-to-process materials such as titanium alloys and nickel-based alloys to meet the stringent requirements of aviation parts. In the electronics manufacturing industry, precision parts processing and circuit board cutting are inseparable from it. It can achieve high-precision processing and meet the strict standards of dimensional accuracy and surface quality of electronic products. In the wood processing industry, whether it is cutting and engraving in furniture manufacturing or wood processing for architectural decoration, carbide octagonal blades can efficiently complete the task. In the stone processing industry, it also plays an important role in cutting, grinding marble, granite, and stone carving.

There are many factors to consider when choosing a suitable carbide octagonal cutter head. The first is the nature of the processing material. If you are processing a material with higher hardness, you should choose a cutter head with higher hardness and better wear resistance; when processing brittle materials, you should pay attention to the toughness of the cutter head to prevent chipping. The second is the processing accuracy requirement. For high-precision processing, the edge accuracy and stability of the cutter head are crucial. In addition, cutting parameters such as cutting speed and feed rate will also affect the selection of the cutter head. Different processing processes require cutter heads with corresponding parameters.

There are many precautions when using carbide octagonal cutter heads. Reasonable control of cutting parameters is the key. Excessive cutting speed and feed rate will increase the wear of the cutter head and even cause damage to the cutter head. Therefore, it is necessary to select appropriate cutting parameters according to the processing material and the performance of the cutter head. It is also necessary to regularly check the wear of the cutter head. When the cutter head is worn to a certain extent, it will affect the processing accuracy and surface quality. At this time, it should be replaced in time. At the same time, do a good job of cleaning and maintaining the tool to avoid corrosion of the cutter head. After processing, clean the chips and residual cutting fluid on the cutter head in time to prevent rust and corrosion, so as to extend the service life of the cutter head.

Carbide octagonal cutter heads play an irreplaceable role in many industries with their unique design and excellent performance. Understanding its characteristics and mastering the key points of selection and use will help to better play its advantages and improve processing efficiency and quality.

RELATED NEWS

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy